Choosing the right type of concrete mixer is crucial for the success of any construction project. Diesel concrete mixers offer unique advantages that make them a popular choice. In this article, we will explore when and why to use diesel concrete mixers, focusing on mobile concrete mixers, hydraulic concrete mixers, portable concrete mixers, and loader concrete mixers. Understanding these factors will help you make informed decisions for your construction needs.

Understanding Diesel Concrete Mixers

Diesel concrete mixers use diesel engines to power the mixing drum. This makes them highly efficient and suitable for various construction projects. They are especially useful in areas with limited access to electricity.

Advantages of Diesel Concrete Mixers

Diesel mixers provide consistent power and performance. They are reliable and can operate in remote locations without electrical infrastructure.

Fuel Efficiency

Diesel engines are known for their fuel efficiency. They can run longer on a single tank, reducing fuel costs and downtime.

Durability

Diesel mixers are built to withstand harsh conditions. They are robust and durable, making them ideal for heavy-duty applications.

Types of Diesel Concrete Mixers

Different types of diesel concrete mixers offer unique benefits. Understanding these types helps you choose the right mixer for your needs.

Mobile Diesel Concrete Mixers

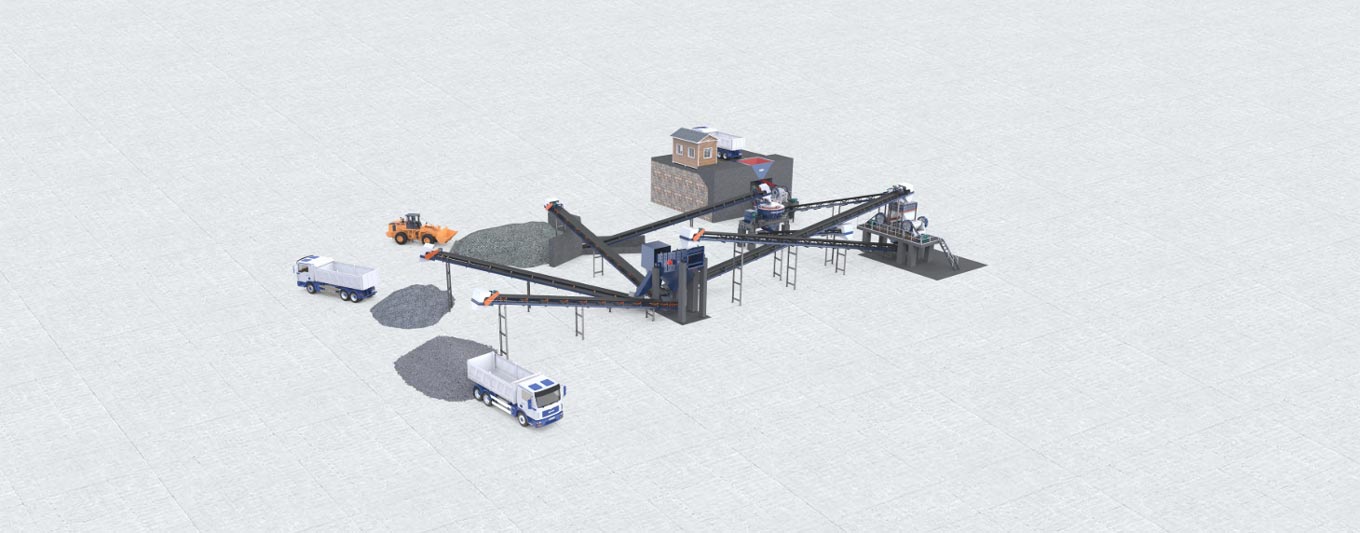

Diesel mobile concrete mixers are versatile and can be easily transported. They are ideal for projects requiring on-demand concrete production.

Hydraulic Diesel Concrete Mixers

Hydraulic diesel mixers use hydraulic systems for efficient mixing. They are suitable for large-scale projects and heavy-duty applications.

Portable Diesel Concrete Mixers

Portable diesel mixers are compact and easy to move. They are perfect for small projects and offer great convenience.

Self-Loading Diesel Concrete Mixers

Self-loading diesel mixers combine multiple functions. They can load, mix, and transport concrete, making them highly efficient.

When to Use Diesel Concrete Mixers

Diesel concrete mixers are suitable for various situations. Knowing when to use them ensures optimal performance and efficiency.

Remote Locations

Diesel mixers are perfect for remote construction sites. They do not require a power source, making them highly versatile.

Large-Scale Projects

For large-scale projects, diesel mixers offer the power and capacity needed. They can handle large volumes of concrete efficiently.

Heavy-Duty Applications

Diesel mixers are suitable for heavy-duty applications. They provide the necessary power and durability for demanding construction tasks.

Why Use Diesel Concrete Mixers

Understanding the benefits of diesel concrete mixers helps you decide why to use them for your construction projects.

Consistent Power

Diesel engines provide consistent power output. This ensures uniform mixing and high-quality concrete production.

Cost-Effective

Diesel mixers are cost-effective in the long run. Their fuel efficiency and low maintenance costs make them an economical choice.

Versatility

Diesel mixers are versatile and can be used in various applications. They are suitable for different types of construction projects.

Choosing the Right Diesel Concrete Mixer

Selecting the right diesel concrete mixer depends on factors such as project size, location, and specific requirements. Each type offers unique benefits.

Project Size

For small projects, portable diesel mixers are ideal. For larger projects, hydraulic or self-loading mixers provide efficiency and high-quality mixing.

Location

Mobile mixers are perfect for remote locations or sites with limited access. Self-loading mixers are also beneficial for on-site production.

Specific Requirements

Consider the specific needs of your project. Hydraulic mixers are best for high-quality concrete with large aggregates. Mobile or portable mixers offer flexibility.

Conclusion

Diesel concrete mixers offer unique advantages that make them a valuable choice for various construction projects. Mobile mixers provide flexibility and on-site production, hydraulic mixers offer powerful and consistent mixing, portable mixers are perfect for small projects, and self-loading mixers offer automation and efficiency. By understanding when and why to use diesel concrete mixers and considering factors such as project size, location, and specific requirements, you can make informed decisions that lead to efficient and successful concrete mixing.